Vertical Packaging Machine with Multihead 10 Head Weighers Without Terrace

Dolzan Multihead weighers meet all requirements of high speed, maximum accuracy, versatility, easy cleaning and maintenance.

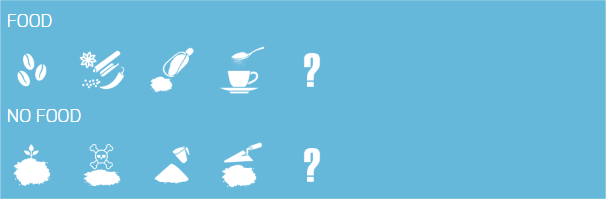

They are suitable to handle granular products: food products:

- biscuits

- dried short pasta

- sweets

- coffee grains

- chocolates

- tea

- snacks

- grated cheese

- rice

- spices

- legumes

- dried fruit

- pet food

- baking products

- frozen products

and non food products

- small bolts and nuts

- electrical and hydraulic parts

- metal and plastic small parts

Dolzan Packaging Machine with 3 Linear Weighers

Vertical packaging machines suitable to make bags starting from a flat foil reel, combined with linear weighers.

Suitable to pack granular products:

- short pasta

- coffee

- rice

- legumes

- dried fruit

- candies

- cereals

- biscuits

- snacks

- pet food

- frozen products

- detergent

Vertical Packaging Machine with Volumetric Dosers for Liquids

Vertical packaging machines suitable to make bags starting from a flat foil reel, combined with volumetric dosers for liquids. T

hese machines are available in special versions and in fully stainless steel construction Aisi 304.

Suitable to pack:

- water

- milk

- edible oil

- engine oil

- juice

- detergent

- shampoo

- sauce

Vertical Packaging Machine With Volumetric Auger Filler

Vertical packaging machines suitable to make bags starting from a flat foil reel, combined with auger fillers.

Suitable to pack powders:

- cacao

- milk powder

- flours

- icing sugar

Vertical Packaging Machine For Vacuum With 2 Linear Weighers

Vertical packaging machines suitable to make bags under vacuum, starting from a flat foil reel.

The OVERALL DIMENSIONS are reduced as the vacuum unit is incorporated in the lower part of the packaging machine; the BAG SIZE CHANGE by means of fixed end parts is very EASY; the equipment is very VERSATILE as the same packaging machine can make, besides vacuumed bricks, pillow bags and flat bottom packs without vacuum.

Vertical Packaging Machine for Vacuum with Volumentric Auger Filler

Vertical packaging machines suitable to make bags under vacuum, starting from a flat foil reel.

The OVERALL DIMENSIONS are reduced as the vacuum unit is incorporated in the lower part of the packaging machine; the BAG SIZE CHANGE by means of fixed end parts is very EASY; the equipment is very VERSATILE as the same packaging machine can make, besides vacuumed bricks, pillow bags and flat bottom packs without vacuum.

Packaging Machine for Flat Bottom Bags with 4 Corner Seals

Vertical packaging machines suitable to make flat bottom bags with 4 corner seals, starting from a flat foil reel.

Suitable to pack granular products

- short pasta

- coffee

- rice

- legumes

- dried fruit

- candies

- cereals

- biscuits

- snacks

- pet food

- detergent

- sugar

and powders

- cacao

- milk powder

- flours

Packaging Machine for Doy Style With or Without Zip

In addition to our wide range of vertical packaging machines from flat foil reel, we have recently launched the new packaging machine D-DOYSTYLE.

Packaging Machine Doy-Style with 2 Linear Weighers

Semiautomatic Filler with Linear Weighers

Semiautomatic filler with linear weighers to fill and pack granular products:

- pasta

- coffee

- rice

- legumes

- dried fruit

- sweets

- cereals

- biscuits

- snacks

- pets food

- detergent

into premade bags and containers

Semiautomatic Filler With Volumetric Screw Doser

Semiautomatic filler with volumetric screw doser to fill and pack powders

- cocoa

- milk powder

- icing sugar

- ground coffee

into premade bags and containers

Semiautomatic Filler with Volumetric Cup Doser

Semiautomatic filler with volumetric cup doser to fill and pack granular products:

- pasta

- coffee

- sugar

- rice

- legumes

- dried fruit

- sweets

- cereals

- biscuits

- snacks

- pets food

- detergent

into premade bags and containers.

Inclined Packaging Machine With 2 Linear Weighers

Packaging Machine with 2 linear weighers D170/2

Inclined packaging machines suitable to make bags starting from a flat foil reel.

Suitable to pack fragile products

- biscuits

- special pasta

Bag Style: pillow bag and square bottom

Weights: from 100 to 1000 gr

Vertical Form Fill and Seal Machines Australia

Sourcing Machinery for Vertical Form Fill and Seal

For businesses producing or packaging small, granular, powder or even liquid food items in bulk quantities or equally small non-food items it is the ideal solution when the final product will reside in a bag. An industry standard for many years, these systems, also called VFFS, have robust capabilities.

As indicated by their name, the packaging takes place in a vertical environment, where it is easy to use a hopper and forming collar tub to dispense a weighed portion of product into a bag. A VFFS machine forms the bottom of the bag, fills it with product, then seals off the top of the bag for a completed product. Does your operation need to acquire hardware with these capabilities?

At Technopak, we make it simple to do just that. With decades of experience and a proven line of packaging hardware, it takes no time at all to get set up with systems that will expand your capacity and improve daily productivity.

A Short Buyer’s Guide to Vertical Form Fill and Seal Machines in Australia

What do you need to know when tasked with sourcing a new vertical packaging machine? Although there is a large amount of information to consider about each unit, here are a few essential areas to consider as you begin looking at our catalogue.

- Look for units with integrated weighing solutions that are both easy to calibrate and accurate to the degree that you require during filling operations.

- Be aware that some machines have different methods of control and operation. For example, some units require an understanding of PLC’s to program and operate correctly. Others have more basic digital systems that require less training. All of our units use HMI touch screen’s with PLC control. HMI touch screens are user friendly and less complicated to understand)

- Special machines are necessary for the packaging of liquids. These units have unique hardware called “volumetric dosers” that ensure only the precise amount of liquid is dispensed into the container package, reducing waste and improving product margins.

What Sets Technopak Apart Regarding a Vertical Form Fill and Seal Machine?

Why partner with Technopak to supply your business with VFFS packaging machine solutions? We understand that partnering with any supplier requires a thorough evaluationþ. Here’s why we’re the right choice for your business:

- We make the buying process as seamless as possible. From assisting your team with determinations about the right equipment to use to furnishing a timely and secure delivery, we emphasise a superior client experience.

- We have the capabilities to meet needs across diverse applications, whether your business handles food or non-food items. The food-safe solutions we source are second to none and comfortably maintain industry standards.

- We can supply the necessary hardware and infrastructure to set up most of your filling system stations, including weighing units that guarantee every bag receives only just the right amount of product.

What to Expect From Our VFFS Baggers

What can our clients anticipate from the actual operation of the VFFS machines we supply? Take a moment to consider some of the critical specifications and characteristics of our vertical form/fill/seal hardware.

- Technopak produces its own range of hardware, including a selection of entry-level machines suitable for businesses just getting started with building out their packaging infrastructure. Please enquire about these options if you are looking for the most cost-effective way to begin packaging in-house.

- Many of the units we furnish are particularly easy to clean and maintain. In food-related packaging operations, and especially those packaging liquids, regular cleaning is essential for the health and safety of the consumer. Ask about these procedures during the sales process.

- Several of our units can draw and maintain a vacuum within packaging during sealing operations. For products that must attain longer shelf lives with robust freshness, this hardware will be the right choice.

Why Technopak is a Cost-Effective Choice for a VFFS Machine

In high-volume environments, packaging hardware faces serious challenges. They must endure many hundreds of thousands of fill cycles without consistent downtime that could cause delays along the entire production line. With Technopak, reliability is never in question. Our solutions are easy to maintain. Because they feature top-quality engineering and materials, they can last longer with appropriate periodic maintenance and deliver better value for your business cycle after cycle.

Contact Technopak now for help.