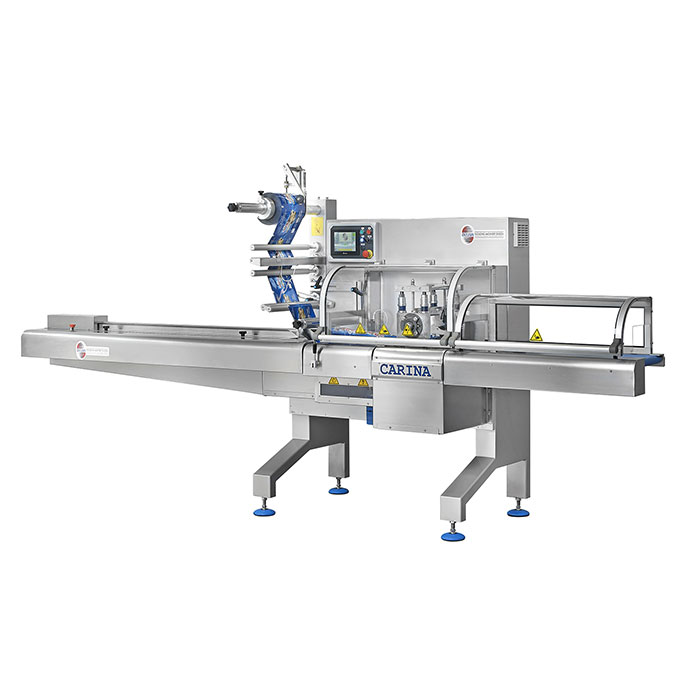

Carina-2015

Electronic Horizontal Flow-Pack machine complete with rotary sealing jaws and Film Roll Holder from the top, composed of:

- Main machine structure in painted steel RAL 9006 and stainless steel AISI 304 guards;

- Cantee-lever style construction with all the mechanical transmissions positioned behind the machine separated from the product flow area;

- 2100mm long infeed conveyor (usable loading space 1400mm approx.) complete with stainless steel AISI 304 deck plates and side guards;

- Food grade nylon pushers and pushers supports;

- Longitudinal fin seal assembly carried out by 2 sets of independent fin wheels diameter 120mm. First set is for pulling , second one is for sealing;

- One up-rotary motion sealing assembly with 240mm wide jaws and transverse or longitudinal sealing pattern complete with inclined cutting knife assembly. Sealing surface width 12,5mm;

- Electronic torque limiter on transverse sealing jaws;

- Motorization by means of 3 brushless motors ,one for the infeed conveyor, one for fin wheels assembly and one for transverse jaws assembly;

- One self centering cantilever film roll holder 500mm wide from the top;

- Discharge conveyor belt one meter long;

- Shock proof Plexiglas safety guards with safety micro switches;

- Color touch screen with the possibility to store up to 99 working programs;

- One adjustable or one fixed forming box;

- Machine direction from left to right as shown on general catalog;

- Pneumatic components: FESTO;

- Machine built in accordance with CE standards;

- Voltage: 400V , 3PH , T+N

Fremont Pouch Machine

Vertical pouch machine fremont – controlled by Plc Siemens

Pouch Machine mod. Fremont to work with pre-formed bags , controlled by PLC

Main features:

- Painted steel RAL 9006 main frame;

- Control panel incorporated to the machine;

- Adjustable bags stacker in relation to the dimensions of the bags

- Suction cups device suitable to pick and drive one bag at a time from the stacker and feed it to the product filling zone;

- Opening of the bag obtained through suction cups and clumps to sustain the bag;

- Pneumatic moving basket to discharge the product inside the bag;

- Sealing system : by hot bar.

- Minimum dimension of the bag: 100 x 100 mm

- Maximum dimension of the bag: width 300 mm x length 430 mm

- Voltage: 400Vac-3Ph+N-50Hz

- Electric power installed: 2,5 Kw

- Compressed air 6 Atm

- Pneumatic plant: Festo Pneumatic

- EC Standard certified

Galaxy 700

Electronic Horizontal Flow-Pack Machine complete with box motion sealing jaws and film roll holder from the bottom, composed of:

- Main machine structure in painted steel RAL 9006 and stainless steel AISI 304 guards ;

- Cantilever style construction with all the mechanical transmissions positioned behind the machine separated from the product flow area;

- 2600mm long infeed conveyor (usable loading space 2200mm approx.) complete with stainless steel AISI 304 deck plates and side guards;

- Food grade nylon pushers and pushers supports;

- Longitudinal fin seal assembly carried out by 3 sets of independent fin wheels diameter 120mm. First set is for pulling , second one is for sealing and third one is for driving pre-heating system and cooling devices. Pneumatic opening of the fin wheels;

- One box motion sealing assembly with 350mm wide jaws complete with guillotine cutting knife assembly;

- Products conveying band under the fin wheels assembly;

- Electronic torque limiter on transverse sealing jaws;

- Motorization by means of 5 brushless motors ,one for the infeed conveyor, one for fin wheels assembly ,one for transverse jaws assembly, one for in-feed conveyor and one for belt under the fin wheels assembly;

- One self-centering cantilever film roll holder 700mm wide from the bottom;

- Motorized film unwinding rubber roller;

- Discharge conveyor belt one meter long with independent motor controlled by inverter;

- Shock proof Plexiglas safety guards with safety micro switches

- Color touch screen with the possibility to store up to 99 working programs;

- One adjustable forming box in width;

- Machine direction from left to right as shown on general catalog;

- Pneumatic components: FESTO;

- Machine built in accordance with CE standards

- Voltage: 400V, 3PH, T+N

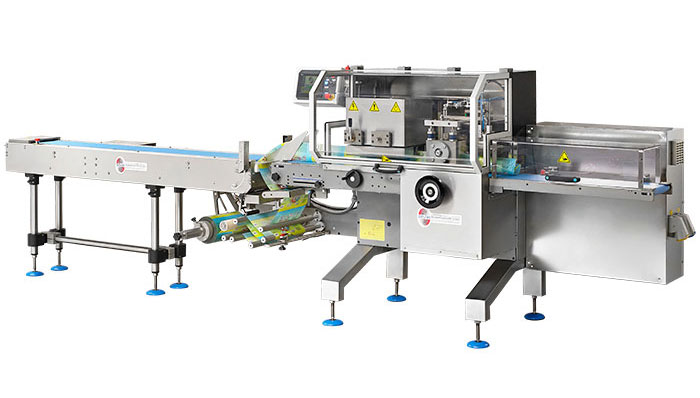

Gemini

Electronic Horizontal Flow-Pack machine complete with rotary sealing jaws and Film Roll Holder from the bottom, composed of:

- Main machine structure in painted steel RAL 9006 and stainless steel AISI 304 guards;

- Cantilever style construction with all the mechanical transmissions positioned behind the machine separated from the product flow area;

- 2100mm long infeed conveyor (usable loading space 1700mm approx.) complete with stainless steel AISI 304 deck plates and side guards;

- Food grade nylon pushers and pushers supports;

- Longitudinal fin seal assembly carried out by 2 sets of independent fin wheels diameter 120mm. First set is for pulling, second one is for sealing;

- One up-rotary sealing assembly with 240mm wide jaws and inclined cutting knife assembly. Standard sealing width 12,5mm;

- Electronic torque limiter on transverse sealing jaws;

- Products conveying band under the fin wheels assembly;

- Motorization by means of 4 brushless motors, one for the infeed conveyor, one for fin wheels assembly, one for transverse jaws assembly and one for belt under the fin wheels;

- One self-centering cantilever film roll holder 500mm wide from the bottom;

- One motorized film unwinding rubber roller;

- Discharge conveyor belt one meter long with independent motor controlled by inverter;

- Shock proof Plexiglas safety guards with safety micro switches;

- Color touch screen with the possibility to store up to 99 working programs;

- One adjustable width forming box;

- Machine direction from left to right as shown on general catalog;

- Pneumatic components: FESTO;

- Machine built in accordance with CE standards;

- Voltage: 400V, 3PH, T+N

Lyra

Electronic Horizontal Flow-Pack machine complete with rotary sealing jaws and Film Roll Holder from the top, composed of:

- Main machine structure in painted steel RAL 9006 and stainless steel AISI 304 guards;

- Cantee lever style construction with all the mechanical transmissions positioned behind the machine separated from the product flow area;

- 2600mm long infeed conveyor (usable loading space 1800mm approx.) complete with stainless steel AISI 304 deck plates and side guards;

- Food grade nylon pushers and pushers supports;

- Longitudinal fin seal assembly carried out by 3 sets of independent fin wheels diameter 120mm. First set is for pulling, second one is for sealing and third one is for driving. Pneumatic opening of the fin wheels;

- One up-rotary motion sealing assembly with 300mm wide jaws and transverse or longitudinal sealing pattern complete with inclined cutting knife assembly. Sealing surface width 12,5mm;

- Electronic torque limiter on transverse sealing jaws;

- Motorization by means of 3 brushless motors ,one for the infeed conveyor, one for fin wheels assembly and one for transverse jaws assembly;

- One self-centering cantilever film roll holder 600mm wide from the top;

- Discharge conveyor belt one meter long, complete of independent motor controlled by inverter;

- Shock proof Plexiglas safety guards with safety micro switches;

- Color touch screen with the possibility to store up to 99 working programs;

- One adjustable or one fixed forming box;

- Machine direction from left to right as shown on general catalog;

- Pneumatic components: FESTO;

- Machine built in accordance with CE standards;

- Voltage: 400V , 3PH , T+N

Tucano

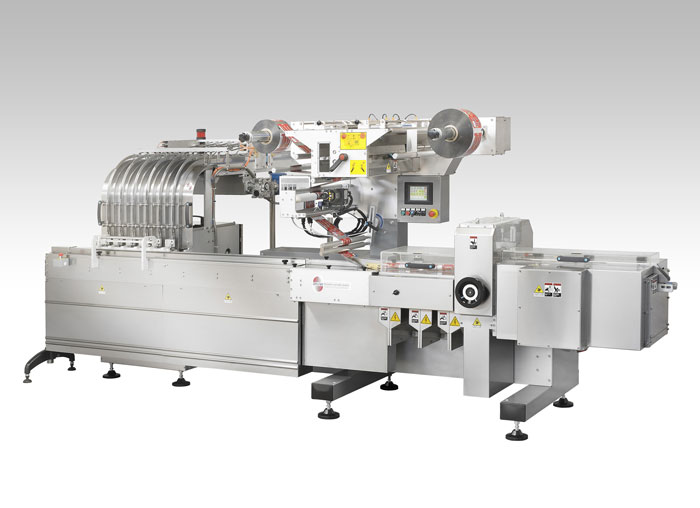

Electronic Horizontal Flow-Pack machine complete with box motion sealing jaws and Film Roll Holder from the bottom, composed of:

- Main machine structure in painted steel RAL 9006 and stainless steel AISI 304 guards , covers and 4 height adjustable feet;

- Cantilever style construction with all the mechanical transmissions positioned behind the machine separated from the product flow area;

- 2600mm long infeed conveyor (usable loading space 1800mm approx.) complete with stainless steel AISI 304 deck plates and side guards;

- Food grade nylon pushers and pushers supports;

- Longitudinal fin seal assembly carried out by 3 sets of independent fin wheels diameter 120mm. First set is for pulling, second one is for sealing and third one is for driving. Pre-heating system and cooling devices. Pneumatic opening of the fin wheels;

- One box motion sealing assembly with 350mm wide jaws and pneumatic guilloting cutting knife assembly;

- Electronic torque limiter with low pressure system on transverse sealing jaws

- Products conveying band to carry products under fin wheels assembly

- Motorization by means of 5 brushless motors ,one for the infeed conveyor, one for fin wheels assembly, one under the wheels and one for transverse jaws assembly and one for closing the sealing jaws;

- One self-centering cantilever film roll holder 600mm wide from the bottom;

- One motorized film unwinding rubber roller;

- Discharge conveyor belt one meter long with an independent motor controlled by inverter;

- Shock proof Plexiglas safety guards with safety micro switches;

- Color touch screen with the possibility to store up to 99 working programs;

- One adjustable width or one fixed forming box;

- Machine direction from left to right as shown on general catalog;

- Pneumatic components: FESTO;

- Machine built in accordance with CE standards;

- Voltage: 400V ,3PH, T+N

Vela-700

Electronic Horizontal Flow-Pack machine complete with box motion sealing jaws and Film Roll Holder from the top, composed of:

- Main machine structure in painted steel RAL 9006 and stainless steel AISI 304 guards;

- Cantilever style construction with all the mechanical transmissions positioned behind the machine separated from the product flow area;

- 2600mm long infeed conveyor (usable loading space 1800mm approx.) complete with stainless steel AISI 304 deck plates and side guards;

- Food grade nylon pushers and pushers supports;

- Longitudinal fin seal assembly carried out by 3 sets of independent fin wheels diameter 120mm. First set is for pulling , second one is for sealing and third one is for driving, pre-heating system and cooling devices;

- One box motion sealing assembly with 300mm wide jaws and complete guillotine cutting knife assembly;

- Electronic torque limiter with low pressure system on transverse sealing jaws;

- Motorization by means of 3 brushless motors ,one for the infeed conveyor, one for fin wheels assembly and one for transverse jaws assembly;

- One self-centering cantilever film roll holder 600mm wide from the top;

- Discharge conveyor belt one meter long with independent motor controlled by inverter;

- Shock proof Plexiglas safety guards with safety micro switches;

- Color touch screen with the possibility to store up to 99 working programs;

- One adjustable width or one fixed forming box;

- Machine direction from left to right as shown on general catalog;

- Pneumatic components: FESTO;

- Machine built in accordance with CE standards;

- Voltage: 400V, 3PH, T+N

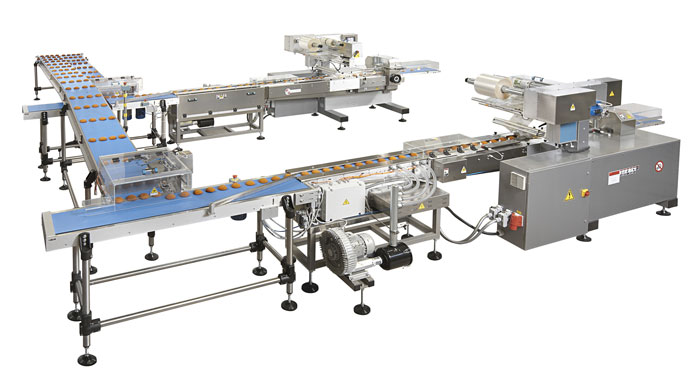

Automated production lines and packaging systems

Secure Your Product with a Horizontal Flow Pack Machine

A horizontal flow pack machine provides your business with numerous benefits such as saving time, consistent packaging, product preservation and more. The horizontal form fill seal machine automatically moves products along the device, wraps them in film and seals the bag at the end to give you a neat and tidy package. It is suitable for a wide range of applications, including baked goods, frozen foods, medical supplies, and other goods. We have an extensive range of bagging machines so that you can select the ideal make and model to suit your requirements.

Benefits of a Horizontal Flow Wrap Machine

Your business can benefit from the numerous advantages of using a horizontal flow wrap machine to package your products.

- The machine will give you fast and reliable automation for high production volumes: Flow packing machines are a cost-effective solution to fast packaging. You can reduce labour costs as you will only require one employee to set the machine and run a programme. Therefore, you can delegate staff to other tasks and increase your productivity.

- There is a low overall cost of ownership: Flow wrap machines are durable with outstanding construction to ensure long life. They have low maintenance levels and high operating efficiency. The machines are user-friendly and have in-built safety checks that can detect if a bag is not present, reducing wastage of bags and products. This feature ensures that your wrapping procedure is consistent, which is ideal when packaging products for export.

- You will get a high-quality package appearance: With state-of-the-art film handling and sealing technology in automated wrapping machines, your packed products will have a consistent and high-quality appearance. This benefit can make your brand more recognisable and professional and improve your inventory as products can be placed together). You can also spend less time counting your stock with our machines product counter function and no product no bag function. You will also further protect your product from damage, contamination, dust, and moisture. Automated packaging is reliable, and ensures there is less human contact with your goods via our sealing technology. The hermetically sealed bags act as a barrier between the internal environment and the external environment delivering both style and protection.

We have an extensive range of multi-function flow wrapping machines.

What You Should Know About a Horizontal Flow Wrapper

A horizontal bagging machine has a different design and structure compared to a vertical form fill and seal machine or a premade pouch packing machine.

- How flow pack machines works: The horizontal machine takes a roll of film and runs it through film guide rollers, a forming box, fin seal wheels and sealing jaws. It manipulates the film and folds the film to accommodate the form set by you. Along the way your film is able to be altered and added to by the machine with a wide range of accessories such as printers, label applicators and more. While your film is being formed your products are placed on the in feed system which can be either a pushing system or carrying system depending on your products needs. It is carried along and placed purposefully in the centre of your bag ready to be sealed, cut and delivered as a finished product on the other end of the machine out feed conveyor.

- Why flow wrappers perform: Flow wrappers are reliable machines with many technologies and principles working in unison in order to deliver your perfect package. The machines can use preheat temperatures, seal heat temperatures and cooling to help weld difficult films and protect delicate products. Flow wrappers can come with servo drives and sensors allowing the machine to always know where every moving part and product is. Certain horizontal equipment is able to automatically change bag dimensions to accommodate products which may naturally vary in length. All of these cutting edge technologies and more are made available to you through us.

- You can achieve all this and fast: like any mechanical process it is not constrained by human limitations. Horizontal flow wrapping is able to performing a multitude of different tasks at speeds that groups of people cannot keep up with. Flow wrappers are so efficient that entire automated feeding systems have been designed in order to pack products at speeds which manual processes cannot come close to replicating. We are able to offer machines to you with feeding systems that have the potential to produce finished quality products at speeds over hundreds per minute.

What You Can Expect from Us Regarding a Horizontal Packaging Machine

We offer a wide range of Delfin packaging machines so that you can select the ideal style to suit your requirements.

- Servo Controlled: Our servo controlled horizontal flow-pack machines comes complete with all the bells and whistles. Its main servo features assist in simplifying product placement and control as the product is guided through the packaging process. Our servo controlled machines make programming and set up easy to understand and implement, minimizing mechanical adjustments which make other flow packers cumbersome and tedious when not outfitted with this technology.

- Stainless steel: Some products must be packed in environments which can cause damage to machine body parts over time. The problems faced by these machines can be overcome by outfitting our horizontal flow pack machines with complete food grade stainless steel bodies. With the extra protection of a fully outfitted stainless steel machine environmental conditions can be made null and void allowing your packaging process to continue and product integrity unspoiled.

- Map packaging: Some products require a modified atmosphere within the packaging they are sealed inside of. We can offer you systems which can accommodate these needs. from gas flushing to vacuum sealing we are able to modify, reduce and extract the internal atmosphere of a bag in order to increase product shelf life and overall freshness.

Our packaging machines are of various lengths to ensure there is a model that will fit your spaceþ.

About Technopak

Our Australian-owned and operated company provides quality packaging equipment for preparing various goods for transport, warehousing, sale, retail and more. We help you to preserve, protect, transport and sell your product with exceptional packaging. You can integrate our machines with printing devices to ensure that your package contains the necessary information. Contact us to discuss the ideal machine for your requirements.